InPlanet’s Science and Impact Lead, Dr. Philipp Swoboda, our research lead on Rock Powders for Tropical Agriculture and Enhanced Weathering, breaks down Life Cycle Assessment (LCA) and its impact on InPlanet. For a deeper dive, understanding Life Cycle Assessment of Rock Weathering is crucial to appreciating the full scope of our work.

To better understand this complex process, we asked Dr. Swoboda to explain InPlanet’s LCA methodologies for our own Enhanced Rock Weathering (ERW) projects. Understanding the life cycle assessment of rock weathering in these projects helps in making informed decisions.

What is a life cycle assessment (LCA)?

LCA, or Life Cycle Assessment, is a method used to measure the environmental impact of a product or process from its first to final application. Dr. Swoboda explains:

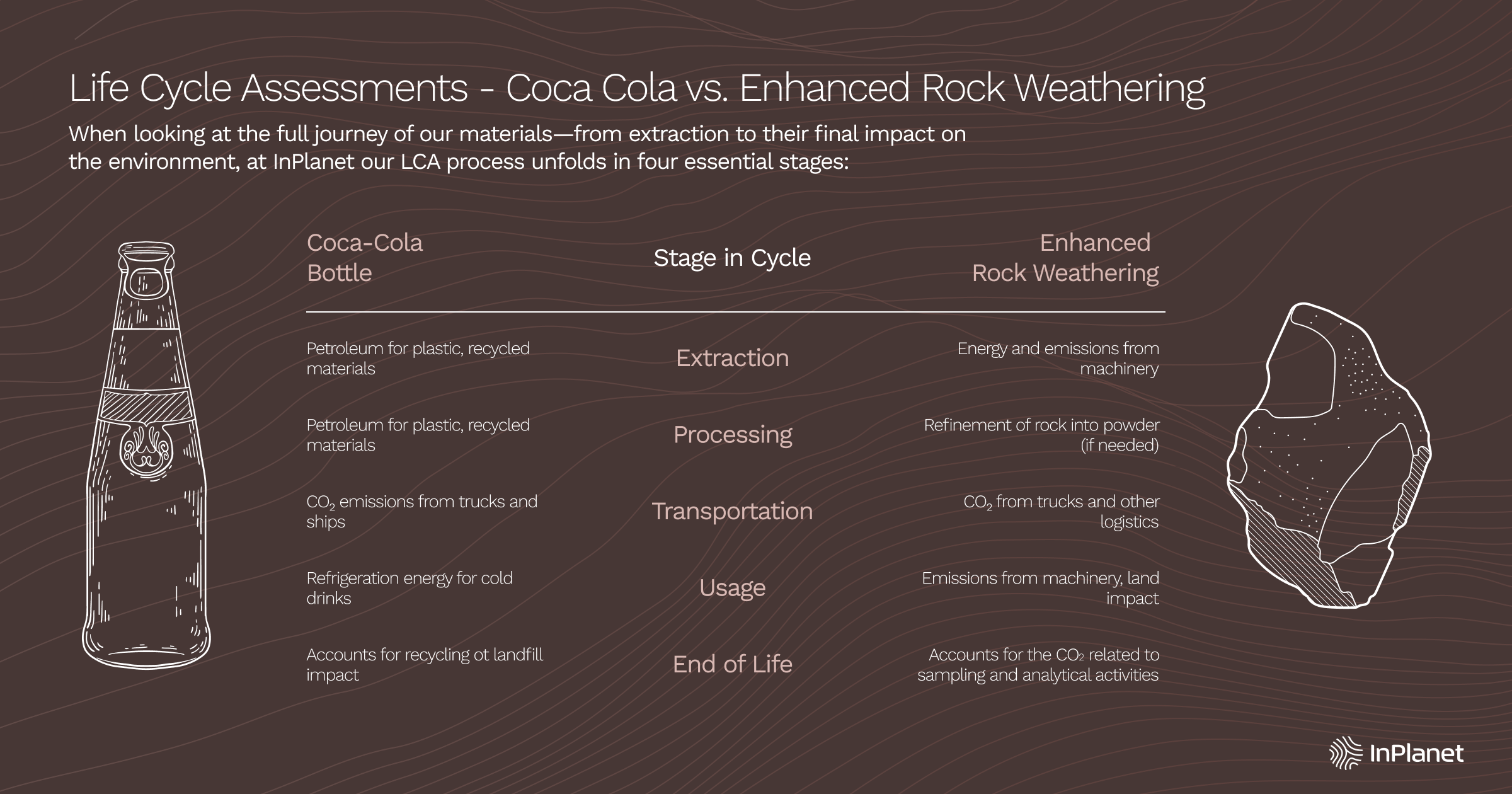

“An LCA aims to measure the environmental impacts of a product or process. For example, a product could be a bottle of Coca-Cola, while a process could be the application of InPlanet’s rock powder. While our business focuses on sequestering CO₂, the entire process, including grinding the rock, processing it, transporting it, and spreading it on fields, also emits CO₂. Ultimately, we aim to quantify the net CO₂ removal.”

LCA in action: Coca-Cola vs. InPlanet’s rock weathering process

A Coca-Cola Bottle‘s LCA Analyzes:

Raw materials (e.g., petroleum for plastic, recycled materials)

Manufacturing (e.g., energy used in bottle production)

Transportation (e.g., CO₂ emissions from trucks and ships)

Consumer use (e.g., refrigeration energy for cold drinks)

End-of-life disposal (e.g., recycling vs. landfill impact)

In contrast, InPlanet’s Rock Weathering Process LCA Examines:

Mining and grinding the rock (energy and emissions from machinery)

Processing into products (if further refinement is needed)

Transporting the rock dust (CO₂ from logistics)

Spreading the rock on fields (emissions from machinery, land impact)

Carbon sequestration monitoring (accounts for the CO2 related to sampling and analytical activities)

Understanding the functional unit in LCA

The LCA begins by defining a functional unit, which serves as the reference unit for all process stages. It defines what is being analyzed and how much of it. Understanding Life Cycle Assessment of Rock Weathering, this functional unit helps ensure consistency in analysis. To illustrate this, imagine a chocolate cake:

“If you want to share it with friends, you need to cut it into slices. Each slice represents a fraction of the whole cake. The functional unit is like that slice: it helps us measure and compare everything fairly. For example, if one person gets half a slice and another gets a full slice, you’re using the functional unit (one slice) to compare who for example who got more or less calories or emitted which amount of CO2 emissions.”

In science and sustainability, we apply the same logic to compare environmental impacts. Whether energy use, emissions, or pollution across different products and processes, the methodology remains the same.

Applying the functional unit to enhanced weathering

Dr. Swoboda explains:

“The standard approach to LCA begins with defining a functional unit. For us, this unit is “one tonne of basalt powder produced and applied to farmland. Unlike other LCA studies that focus solely on rock powder production, we assess the entire process, from rock sourcing and processing to spreading the basalt on agricultural land. We even include our MRV monitoring emissions.”

InPlanet’s four stages of LCA

When looking at the full journey of our materials, from extraction to their final impact on the environment, at InPlanet our LCA process unfolds in four essential stages:

1. Raw Material Sourcing: This is where it all begins. We extract and prepare the rock, ensuring it’s suitable for enhanced weathering. The goal is to source responsibly, balancing efficiency with environmental impact. This stage is fundamental in understanding Life Cycle Assessment of Rock Weathering.

2. Processing & Manufacturing: Once extracted, the rock is crushed and refined into a form that maximizes its CO₂ absorption potential. We carefully optimize this step to enhance dissolution rates while keeping energy use in check.

3. Transportation & Distribution: Getting the material where it needs to go is just as crucial. We focus on minimizing emissions during transport. By working closely with logistics partners, we streamline the supply chain and reduce our footprint.

4. Application & End-of-Life: Finally, the rock is spread across agricultural fields, where it starts working its magic; capturing CO₂ and improving soil health. We measure its dissolution over time, ensuring that we can quantify the long-term climate benefits.

By following these stages, we ensure that every step of the process is as sustainable and effective as possible.

Challenges in LCA: emissions accounting

Dr. Swoboda elaborates:

“To illustrate the scale of data collection, we had to track every stage of basalt’s journey. When you blast a rock front, transport boulders to a quarry, and crush them into fine powder, each step requires data on energy use, machinery running time, and fuel consumption. This was a painstaking process, requiring close collaboration with farmers, transport operators, and mining engineers.”

The real challenge in understanding Life Cycle Assessment of Rock Weathering is emissions accounting, accurately quantifying emissions from various sources. Transportation emissions, in particular, often have the biggest impact.

“Interestingly, transportation had even more emissions than the grinding process. That means logistics of getting rock from the quarry to the field are a critical factor. We also had to account for emissions from our field monitoring activities, such as driving to sites, collecting samples, and conducting analysis.”

LCA calculations always come with some level of uncertainty; that’s just the nature of working with environmental data. Variability in conditions and data sources makes it tricky to pin down exact numbers. As Dr. Swoboda puts it:

“Uncertainty discounts are a crucial part of the LCA process. We’re dealing with open systems, and it’s almost impossible to be 100% certain about our numbers. So, we apply conservative estimates to ensure credibility. Our final estimate was 18.25 kg of CO₂ emitted per ton of rock applied. That means for every ton of basalt spread on a field, we must deduct this amount from our carbon sequestration calculations.”

The role of LCA in carbon credit verification

For carbon removal projects, an independently verified LCA is crucial for issuing carbon credits. Dr. Swoboda underscores the importance of transparency:

“Buyers of carbon credits want to know the net impact. That means they expect rigorous, science-backed assessments. Our LCA is independently validated, ensuring that our CO₂ removal claims are credible. This is essential for building trust in the voluntary carbon market.”

The future of LCA in ERW and beyond

As technology advances, automation, remote sensing, and AI-driven data analysis will improve LCA precision for understanding the Life Cycle Assessment of Rock Weathering. Dr. Swoboda concludes:

“The science behind LCA is always improving. The more data we collect, the more refined our models become. In the long term, we may see more predictive modeling, but right now, detailed primary data gathering the gold standard.”

LCA is a critical tool for businesses, policymakers, and scientists working to mitigate climate change. Through meticulous data collection and rigorous analysis, our experts like Dr. Philipp Swoboda are helping shape the future of sustainable industries.